Muc-Off’s 700-Hour Chain Propels Ganna To Hour Record Success

09.10.2022, FOR IMMEDIATE RELEASE —

Muc-Off, the global leaders in bicycle and motorcycle care and maintenance share details of their seven-hundred-hour investment into Filippo Ganna’s UCI Hour Record success.

The 8th of October 2022 will go down as a landmark moment in cycling history. Filippo Ganna’s staggering Hour Record distance of 56.792km (35.289 miles), showed the world what can be achieved when you combine raw talent with industry-leading data analysis, and uncompromising preparation.

Muc-Off's involvement with the record included seven-hundred-hours of their research and development team’s cumulative time. They began working with INEOS Grenadiers Performance Engineer Dan Bigham back in May of this year, supporting his emphatic hour-record success with everything from drivetrain componentry selection to the ultrasonic optimisation of the chains and chain rings used. Following months of testing, learning, and refining, and with one hour record in the bag, Bigham would revert from rider back to Performance Engineer, utilising the learnings he and Muc-Off had amassed to support Ganna in bringing down his own record.

The result of their efforts amounted to a chain which was over 30% more efficient that the stock component, and 7% more efficient than the optimised chain supplied for the Bigham record.

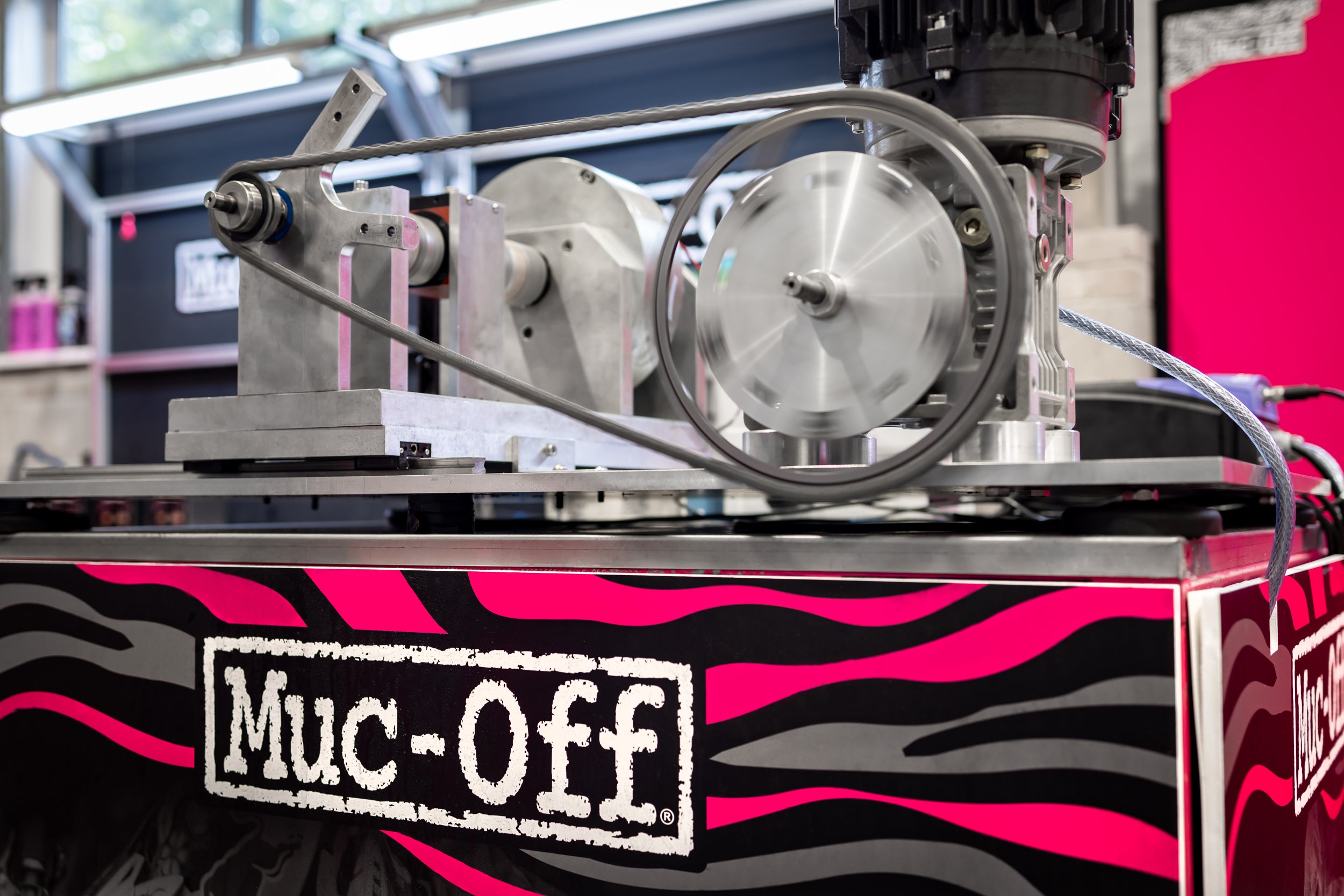

A unique coating was applied to Ganna’s rear sprocket exclusively for his record, an element which Muc- Off managed to test and develop in the two-month period following Bigham’s attempt. The materials which make up the coating remain a closely guarded secret, but Muc-Off have confirmed that during lubricated contact pressure testing on their tribo-lab, the coated rear sprocket produced a 52% reduction in the coefficient of friction, when compared to the bare steel version used by Bigham. The performance test completed on their dynamometer, which simulates the ‘on-track’ performance, showed a final decrease in wattage loss of 4.2%.

“Working so closely with Muc-Off in the last few months, their dedication and passion for drivetrain optimisation and their focus on delivering efficiency is unrivalled. They added a massive 87m to my record, and then to come in with a new innovation like the rear sprocket coating, finding a further 7% efficiency gain for Filippo, is testament to their tenacity for performance. Seven-hundred-hours is an incredible time investment, and I’m thrilled to see their efforts rewarded with this Hour Record achievement.” Dan Bigham, Performance Engineer at INEOS Grenadiers.

The majority of Muc-Off’s seven-hundred-hour investment was accumulated prior to the testing stage. Before testing could begin, the team had to design and manufacture new hubs for their dynamometer to fit the new centre lock and track thread standards. Given the tight timeline facing INEOS, Muc-Off took drawings of the chosen hub, redesigned them in CAD, and produced 3D-printed test versions of the hub to determine their effectiveness, before committing to the manufacture of the final steel version.

Once the steel hub and the various bike componentry options arrived from the team, the component selection process began, including the testing of each combination of chain, sprocket, and chain ring, with tests having to be completed multiple times to verify the results. Add to this, nine rounds of Muc-Off’s eleven step, Ultrasonic Optimisation process, which took nearly twenty-five hours to complete for each of the four chains supplied, and you start to understand the time investment required when operating at the pinnacle of drivetrain performance.

“I am so proud of the team and what’s been achieved. We’ve helped make history once again and it’s thanks to the hard work of our staff, and the investments we’ve made into technology. Since 1994, we have been obsessed with innovation, particularly in drivetrain optimisation. The last decade has seen us build incredible momentum, working with the best teams and athletes to make special moments happen – This is yet another one of those special moments, and we’ll use the experience gained from breaking this record to continue pushing the boundaries in everything we do.” - Alex Trimnell, CEO, Muc-Off.

With this latest success story, Muc-Off can now boast involvement with three Hour Records, twelve Grand Tour wins, and a collection of Olympic, Paralympic, and Commonwealth Games medals, just in the last ten years.

So, what makes Muc-Off’s drivetrain optimisation process so advantageous?

The UK-based brand has shown an unrivalled commitment to scientific development and have invested heavily in industry leading equipment and expertise, which has supported their ability to deliver class-leading levels of data and support to professional riders. Since 1994, Muc-Off have been using advanced testing methods to study the many moving and interacting surfaces found in bike chains, and the multiple engagements that occur in relative motion.

Investments into key pieces of equipment such as their TriboLab, which is used to measure friction and wear in microscopic detail have also been instrumental, allowing them to develop testing protocols rooted in repeatability and reproducibility. The TriboLab gives Muc-Off broader testing capabilities, faster changeover between configurations, higher levels of accuracy and repeatability, and real-time control and data analysis. This all comes thanks to add-on modules, which cater for a wide variety of standard ASTM tests, as well as its own bespoke cycling tests, developed through a British Government funded partnership with the National Physical Laboratory (NPL).

The secret to Ganna’s successful record attempt was in the methodical and repetitive approaches taken at every stage of the testing process; learning and improving run after run. Muc-Off’s ability to deliver consistently exceptional optimisation results is what separates them from the competition and is a primary reason why they’re the brand of choice for the world’s greatest teams and athletes.

The build-up and execution of the Hour Record is testament to Muc-Off’s performance obsession. Their Performance Hub which can be found at Muc-Off.com, details all the ground-breaking innovation that happens behind the doors of their UK-based super lab. The site features product development stories, along with a multi-chapter series, detailing the work that goes into developing their record-breaking products - from the equipment used to the environmental factors they consider. To learn more about this, and the full story of their Hour Record preparations head to: muc-off.com/pages/performance-hub.